Military product know-how you can depend on.

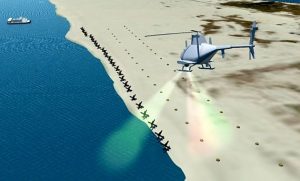

Military products can face harsh environments that test quality, reliability and durability. Ascentron builds Printed Circuit Board Assemblies (PCBA), Flex Circuit Assemblies, and Electro-Mechanical Assemblies for our military customers. Products we manufacture are found on unmanned aerial vehicles (UAV), helicopters, aboard Navy ships, and in missile systems. Military projects often require obsolete or hard-to-procure components. We have well established dependable sources to help support these projects. We can also work with an outside service to convert lead-free/RoHS Ball Grid Array (BGA) and other components into leaded components if necessary for a project.

We are International Traffic in Arms Regulations (ITAR) registered and have an Export Management and Compliance Program (EMCP) in place to ensure compliance with ITAR and Export Administration Regulations (EAR). These vital United States export control laws affect the manufacturing, sales, and distribution of technology. We are also a certified Woman Owned Small Business (WOSB), which may provide an advantage for government related projects that require diversity in the supply chain.

Quality you can count on.

Our Quality Management System is AS9100D Certified. Our system has been audited and approved by leading Aviation and Military companies. Lean manufacturing principles and in-process quality controls are in place throughout our assembly process to minimize potential defects and to enable immediate responses to problems.